• Production Description

• Specification Specification

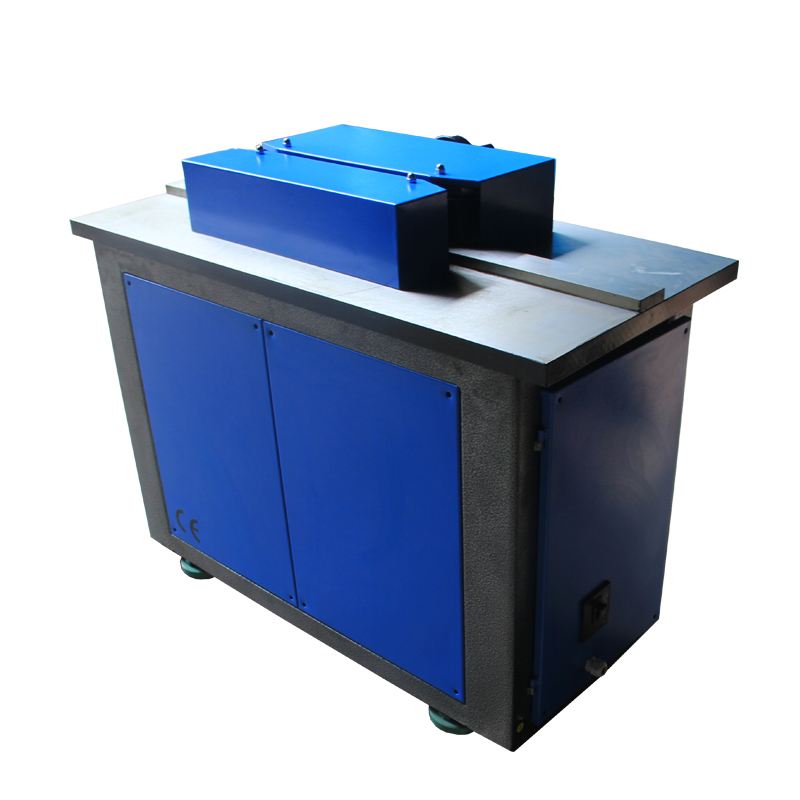

| Model No. | BT-1500DP |

| Working Length | Unlimited |

| Max. Working Thickness | 80mm |

| Power Supply | Single phase AC220V+/-10%, or 3 phase AC380V +/-10%. For USA and Canada, we can design the electricity circuit specially, so that it will fit local power supply directly without tranformer. |

| Rotation Speed of Spindle | 2000-20,000rpm |

| Cutting Speed | 0-1000mm/min (600mm/min is the best working status) |

| Spindle Ending Beat | ≤0.01mm |

| Workbench Beeling Tolerance | ≤0.05mm |

| Diameter of Dust Collector Mouth | 60mm (combined with machine) |

| Gross Power | 5.5kW |

| Cutting Depth | 0-0.5mm adjustable |

| Cutting Mode | Material feeding |

| Machine Dimension (L*W*H) | Crate of Machine:122*70*113cmCrate of Dust Collector: 65*55*61cm. |

| Gross Weight (including free-fumigation wooden case) | 480kg |

| Certificate | CE, ISO9001, ISO14001 |

• Application

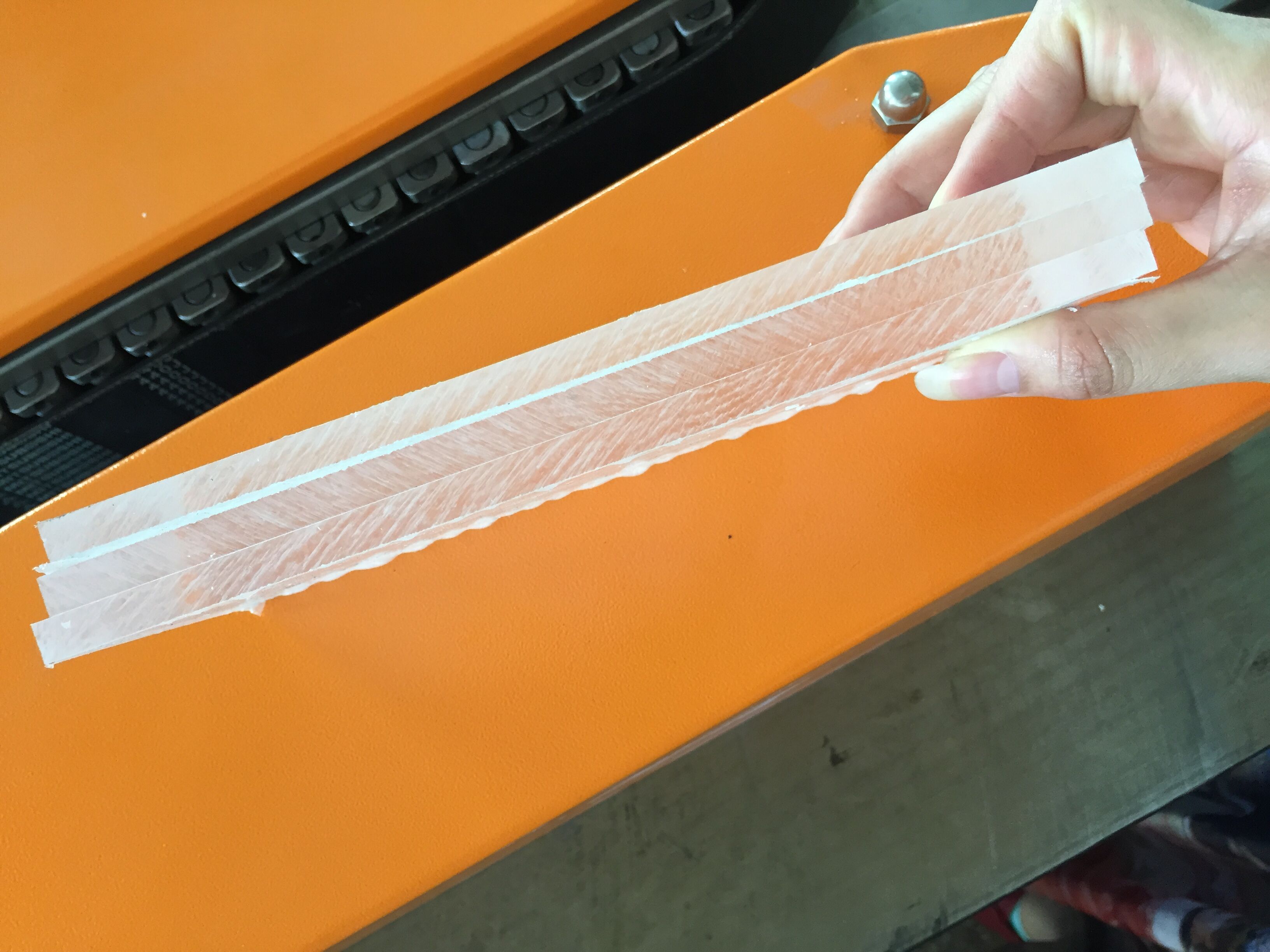

In traditional plexiglass products processing, the workers always use bench polisher or flame polisher to polish the plexiglass surface, whose disadvantage is low efficiency, high labor cost, large wastage but the polishing finish is not perfect.

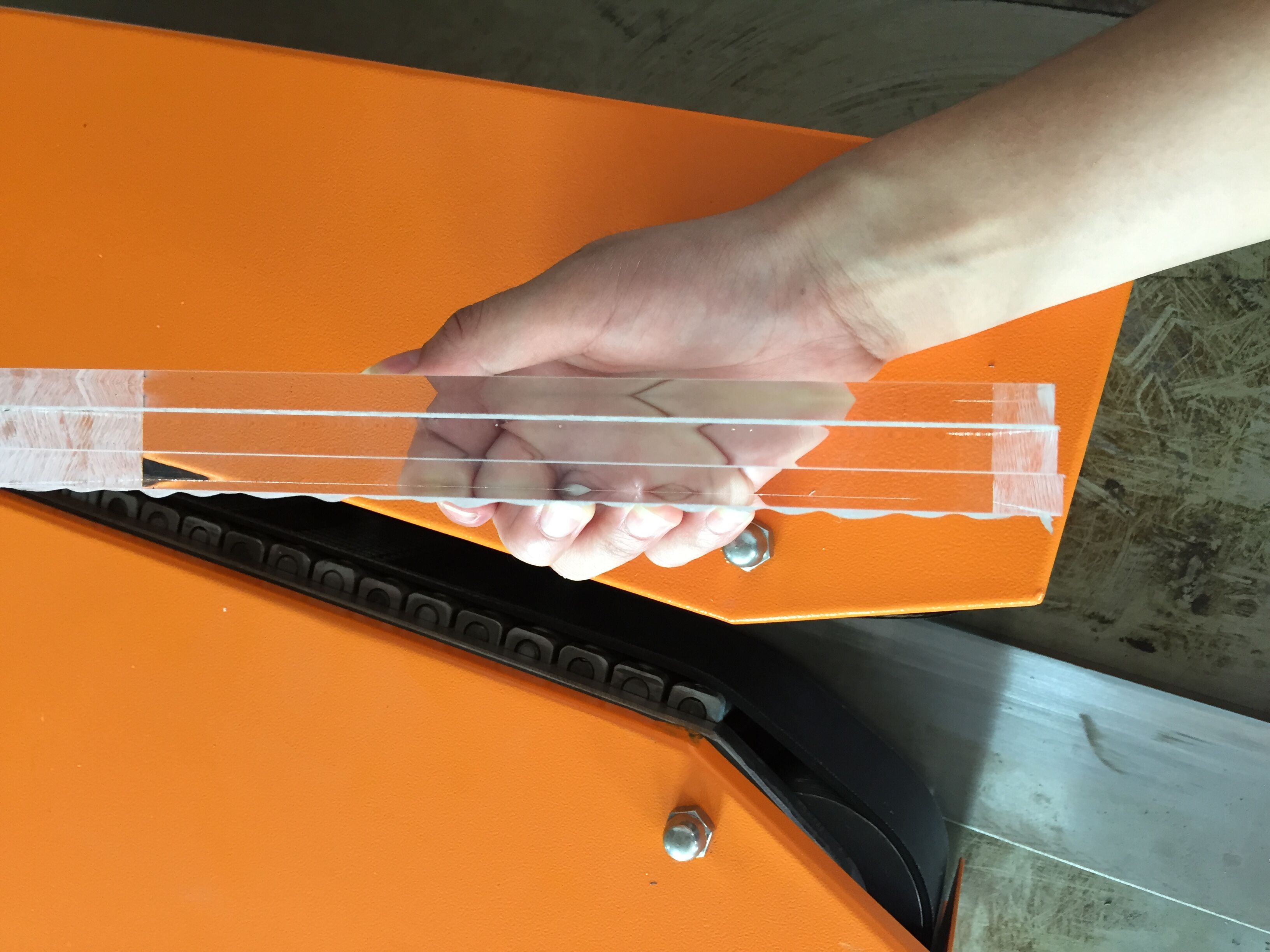

The Diamond Edge Polishing Machine, adopts Monocrystal and PCD tool to cut plexiglass finely so to get mirror finish surface. After polished, the products are high transparent, non discoloring, , especially perfect as light guide plate.

Before Polished.

After Polished

•Technical Feature

1) High efficiency, and low labor cost.

2) Low wastage of material.

3) High precision, the cutting thickness is adjustable from 0-0.5mm.

4) Environment friendly, no powder, low noise and low energy.

5) Automatic polishing by machine, reduce labor injury.

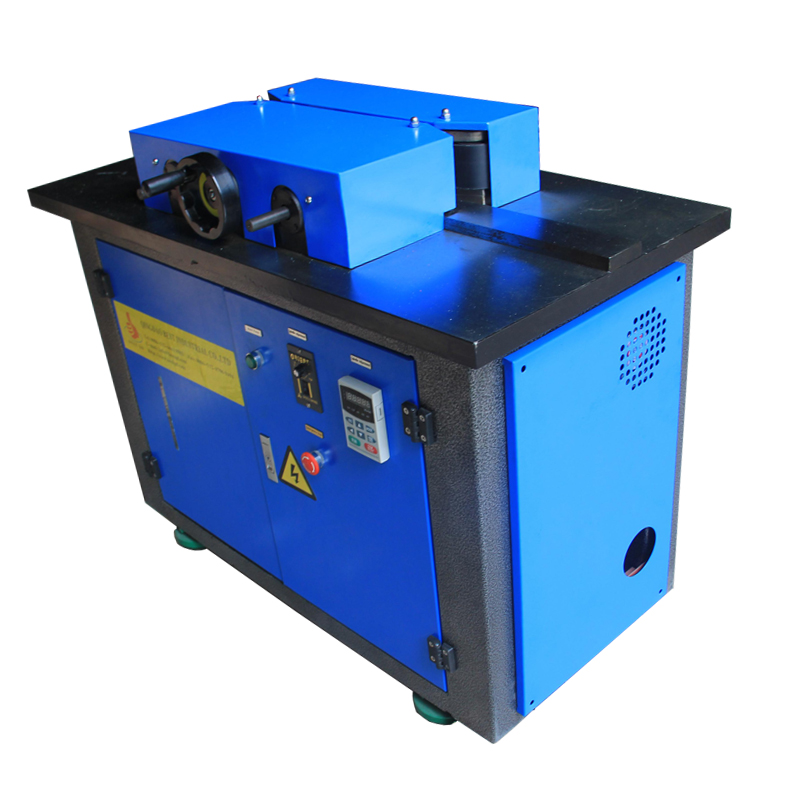

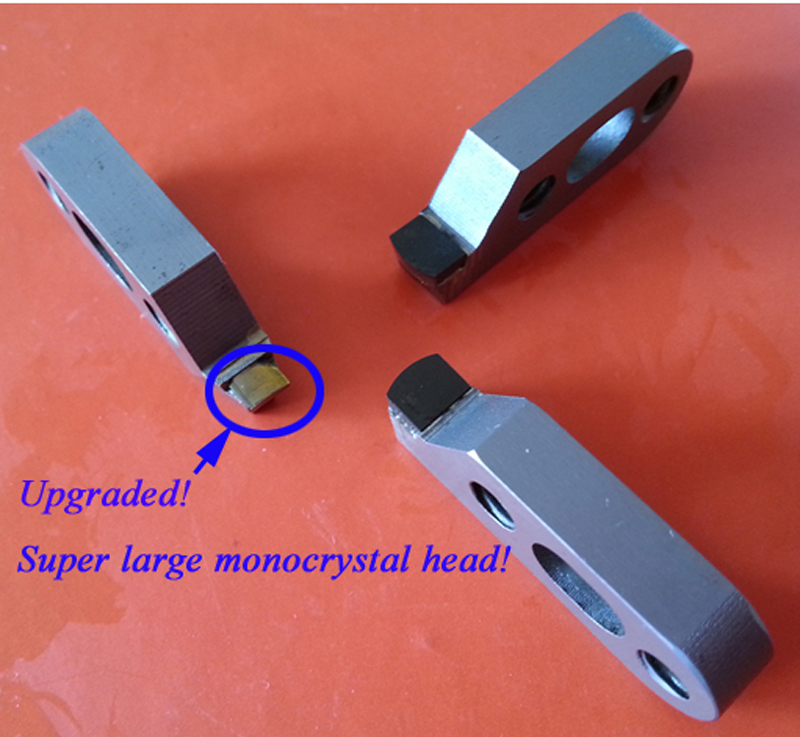

● Cutting Tools

The machine is equipped with 1pc of monocrystal diamond cutter and 2pcs of PCD diamond cutters.

Diamomd cutters purchasing link to aliexpress.com.

https://www.aliexpress.com/store/product/High-Quality-diamond-milling-cutter-3pcs-set-including-2pcs-of-PCD-rough-cutters-and-1pc-of/904631_32731115982.html?spm=2114.12010612.8148356.7.13317a56mJdjmN

• Packing List

| Item Name | Quantity |

| BT-1500NDP Upgraded Diamond Edge Polishing Machine | 1set |

| Full set of vacuum Dust Collector | 1set |

| Inner hexagon spanner | 1set (in toolbox) |

| Cutter head and cutters including 1pc of monocrystal diamond cutter and 2pcs of PCD diamond cutters | 1set (equipped on the machine) |

| Calibration disc for cutters | 1pc (in toolbox) |

| A screw for disassembling cutter head | 1pc (in toolbox) |

| Dialgauge | 1pc (equipped on the machine) |

| Feeler | 1set (in toolbox) |

| User’s Manual | 1book |

● Lead Time

7 days dating from payment is received.

When you place order, please kindly advise us which kind of power supply you need, single phase AC220+/-10%, or 3 phase AC380+/-10%, or special electricity circuit for USA and Canada countries and areas.

● Warranty

2 years dating from you receiving the machine.

During warranty period, if some part is broken due to manufacturing defect, we will send you new part to replace freely.

● Payment Terms

L/C, T/T, Western Union, MoneyGram, PayPal, Alibaba Trade Assurance, Credit Card through aliexpress etc.

● Packing Information

The Diamond Edge Polishing Machine and the Dust Collector are packed in 2 separate wooden crates:

Crate of Machine:122*70*113cm

Crate of Dust Collector: 65*55*61cm.

● Suggested Shipping Mode

By sea or by air.

We also can arrange shipment to your door directly. If you need delivery to door service, please kindly advise us your address in details including door number, street number, city name, zip code etc for our checking total shipping cost to door.

• Working Room

• FAQ (Frequently Asked Questions)

Q. What should we prepare for the machine?

A: 1) Power supply. Single phase AC220V +/- 10%, or 3 phase AC380V+/-10%, according the machine you purchased.

2) Water. For cooling system.

Q. What is consumable material of the machine?

A: Just cutters are consumable part of the machine.

Q. What is cutters’ working life?

A. In normal condition, the cutters working life is 8hour/day*30 days / month * 2.5 months=600 hours.

Q. When the cutters become dull, should we abandon them directly?

A: No. They can be resharpened then be used again.

You buy machine from us, we resharpen cutters for you during the whole lifespan of the cutters freely.

• Contact Us

If you are interested in this machine, welcome to send inquiry to us.

Or contact us for more details of the machine.