- Condition:

- New

- Place of Origin:

- China (Mainland)

- Brand Name:

- BEST or OEM

- Model Number:

- BT-1200BDW/BT-1800BDW/BT-2400BDW

- Machine Type:

- Hot bending

- Raw Material:

- Flat sheet

- Material / Metal Processed:

- Plastic

- Power:

- Electric and pneumatic

- Automation:

- Automatic

- Extra Services:

- Heat Treating

- Certification:

- CE

- After-sales Service Provided:

- Overseas third-party support available

- Name:

- Double wires automatic acrylic bending machine

- Model No.:

- BT-1200BDW / BT-1800BDW / BT-2400BDW

- Working length:

- 0-1200mm / 0-1800mm / 0-2400mm

- Heater type:

- heating wires

- Heater quantity:

- 2pcs parallel

- Bending width:

- Unlimited

- Bending thickness:

- 12mm. Thicker plate has to be milled V-groove in advance

- Angle range:

- 45-180 degree bent automatically. Less 45 degree bent by hand

- Max. distance between 2 wires:

- 500mm adjustable

- Min. distance between 2 wires:

- 100mm adjustable

Packaging & Delivery

- Packaging Details

- New Product Plastic Double Heating Wires Automatic bending machine Export standard free-fumigation wooden case

- Delivery Time

- 5 days after deposit is received.

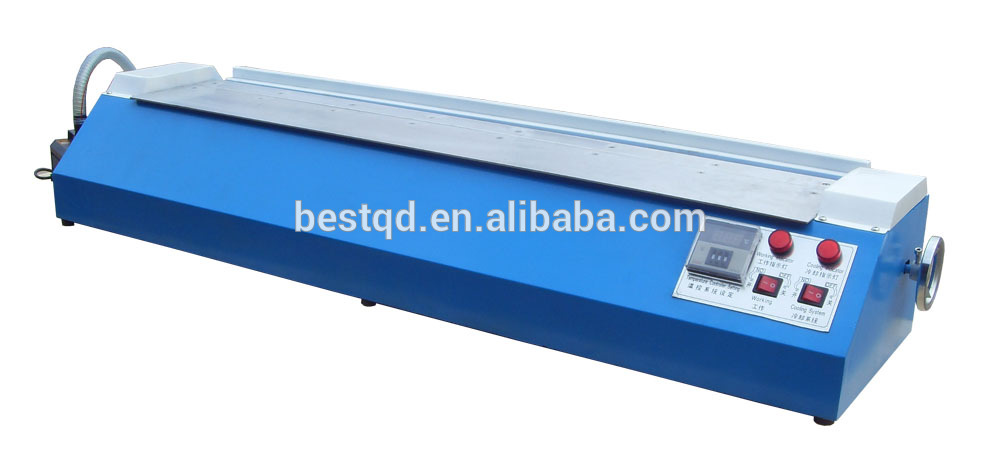

New Product Plastic Double Heating Wires Automatic bending machine

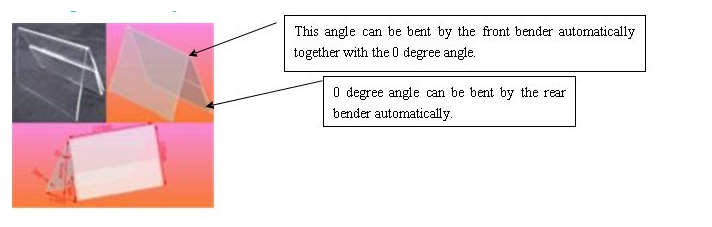

Picture show:

Technical Parameter:

|

Model No. |

BT-1200BDW |

BT-1800BDW |

BT-2400BDW |

|

Bending Width |

0-1200mm |

1800mm |

2400mm |

|

Max. Bending Thickness |

12mm bent automatically. Thicker than 10mm thick sheet needs milling V-groove in advance. |

||

|

Angle Range Formed by Front Bender Automatically |

45°-180°adjustable(for 0°-45°, you can heat and soften the sheet on the machine then form angle manually.) |

||

|

Angle Range Formed by Rear Bender Automatically |

0°-180°adjustable |

||

|

Max. Distance Between 2 wires |

500mm |

||

|

Min. Distance Between 2 wires |

100mm |

||

|

Heater Mode |

Heating wires |

||

|

Heating Wires Q’ty |

2pcs |

||

|

Heating wire Power |

380W/pc |

390W/pc |

400/pc |

|

Gross Power of Machine |

860W |

880W |

900W |

|

Input Voltage |

Single Phase AC220V +/-10% , 50-60Hz Or 3 Phase AC3380V+/-10% |

||

|

Machine Dimension |

1950*950*1150mm |

2550x950x1150mm |

3150*950*1150mm |

|

G.W. |

200kg |

300kg |

360kg |

Technical Feature:

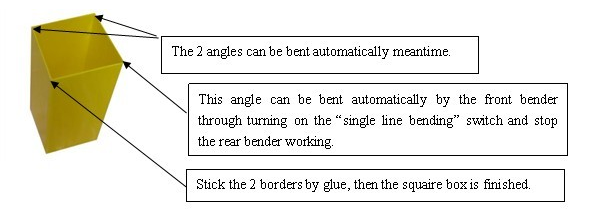

1. 2 heating lines:

Comparing with single line bending machine, this model has 2 heating lines so that it can heat and bend max. 2 angles meantime automatically, so 2 times higher working efficiency than single line bending machine.

2.Heating wires:

Comparing with heating tube model, the machine is equipped with heating wires, the angle bent by heating wire is more accurate and sharper.

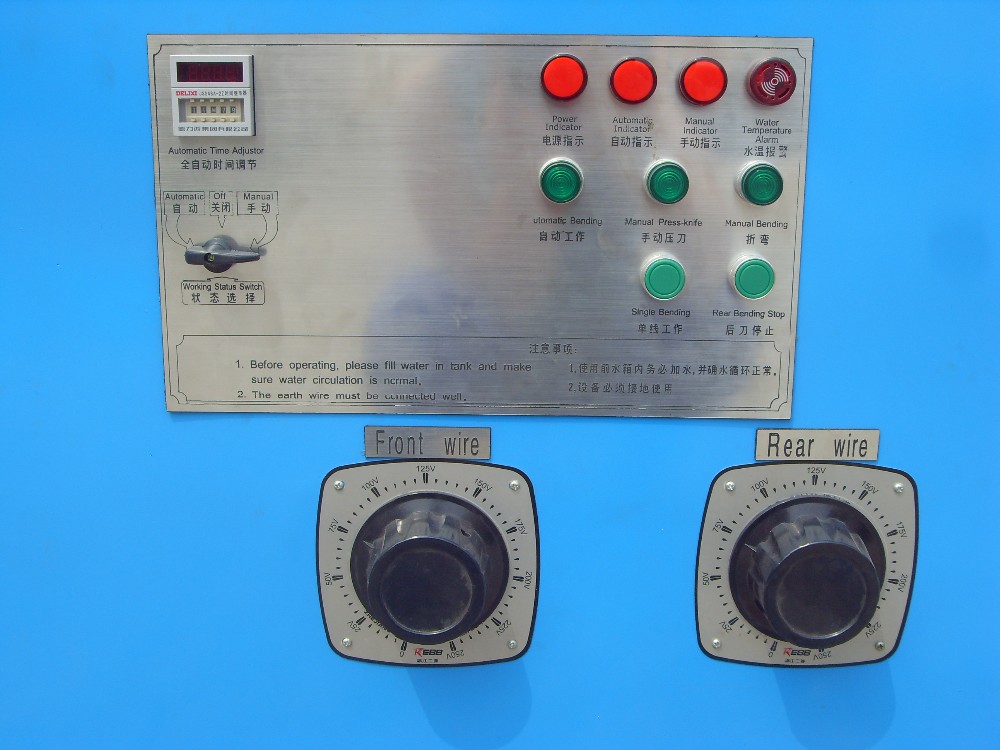

3.Wires controlled individually:

Each heating wire is controlled individually. You can make them work meantime, or just select one work and the other power off.

4. Voltage regulators:

Heating voltage of each wire can be adjusted and set by separate voltage regulator. Max. Value of each voltage regulator is 75V.

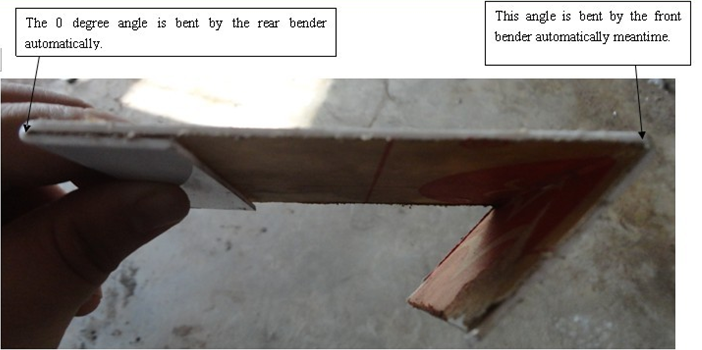

5. 0 degree angle shaped:

Besides all of function of the single line bending machine, one of its largest advantages is the rear bender can form 0 degree angle automatically with high accuracy, so to save working time and labor cost than form it by hand.

6. Angle adjustable:

It is equipped with screw rods to adjust angle as well as angle meters, both of the angle are adjustable as demand.

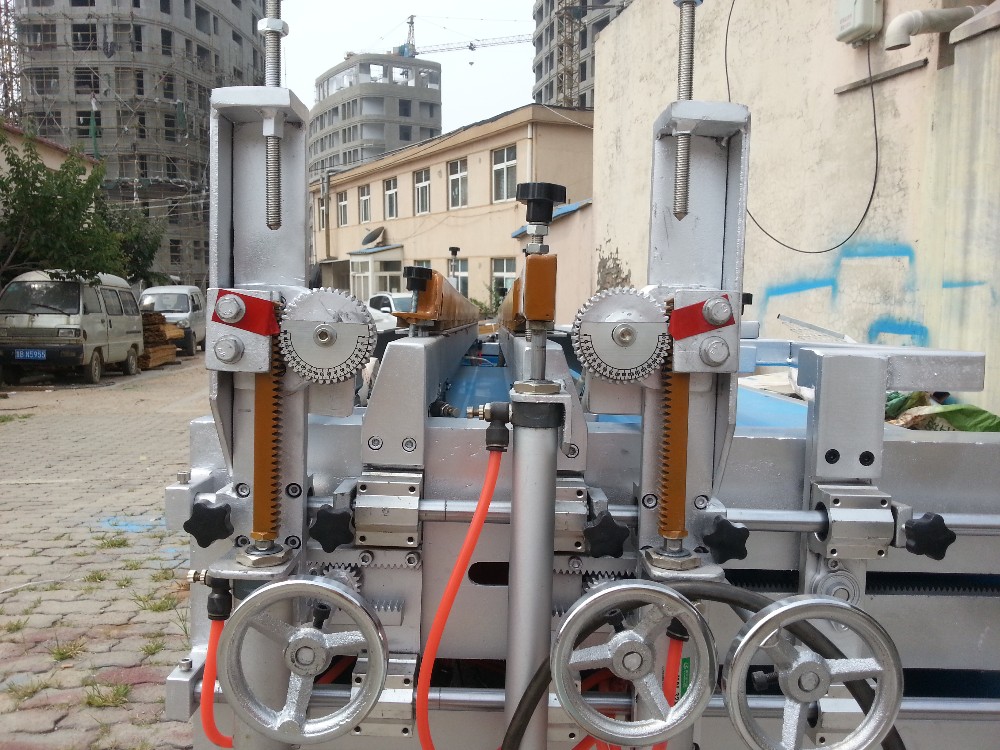

7. Heating gap adjustable:

The heating gap is adjustable through the hand wheel, generally speaking it should be 3-4 times of the acrylic thickness. Take 3mm thick acrylic sheet for example, the heating gas should be set as 9-12mm width.

8. Distance adjustable:

The distance between the front bender and the rear bender ( means the distance between the 2 angles) are adjustable as requirement. Max. distance is 500mm. Min distance is 100mm.

9. Single bending:

If you don’t need to form 2 angles meantime, please turn on the “single bending” switch, then the rear bender will stop working.

10. Rear Bending Stop:

When you need to bend 0 degree angle by the rear heating wire, please press Rear Bending Stop. In this case, the rear press-knife will not come down, so that the rear work tables can fold and repeat completely without press-knife block in the middle.

11. Water Cooling:

Perfect water circulation cooling system including water pump, water pipe and water tank. Furthermore a temperature sensor is built in the machine, when water’s temperature in pipe is over 50℃, the machine will alarm automatically. Water chiller is optional according to clients requirement.

12. Back Ruler:

The machine is equipped with back ruler, it is mainly used to locate acrylic sheet, especially in mass production is quite useful, you don’t need to set every sheet’s position one by one, so to improve working efficiency, also keep the high uniformity in mass production. It’s adjustable forward and backward according to requirement. When you don’t need it, you can disassemble it.

13.Working mode switch:

Manual working mode and Automatic working mode for your selecting freely.

Application:

It can bend acrylic (organic, PMMA, plexiglass), plastic, PC, PVC, PETG, PP, ABS etc. The rear angle can be bent from 0 degree to 180 degree automatically. The front angle can be bent from 45 degree to 180 degree automatically. It is a necessary equipment for AD sign products making industry. Proper for sample making and mass production.