When my HHO Generator gas production is insufficient, or small amount of gas from the torch nozzle, what should we do?

Dear friend,

Thank you for your purchasing the HHO Generator from us.

Generally speaking, the situation of insufficient gas output is mainly caused by below situations. Please kindly check and do according to the relevant solutions as below:

Situation 1. The electrolyte is contaminated and invalid, or the electrolytic cylinder is worn out or damaged.

Solution: Please check the AMP meter to see what value it is. The normal AMP value should be over 10A-12A.

If the current value on your machine is less than 10A, please replace with the new electrolyte and check the current value of each electrolytic cylinder (normal 10A-12A). If the current value is still lower than 10A, please replace the electrolytic cylinder with a new one.

Situation 2. There is gas leakage.

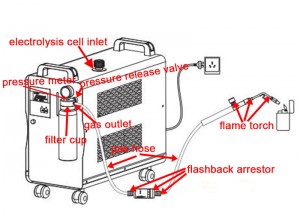

Solution: Check the machine body and gas hose and flame torch if there is leakage, especially on the connections parts.

Turn off the flame torch, turn on the machine, apply soapy water to the connection points of the machine, outlet pipe and flame torch, and check the leak point for maintenance.

Situation 3. The gas flow is not smooth.

Solution: 1) Maintain or replace the flame arrestor and the damper inside the flame torch.

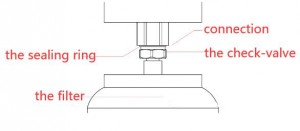

2) Open the filter and loosen the check-valve counterclockwise to keep a certain gap (1-1.5mm) at the interface, but ensure that the sealing-ring can not leak.

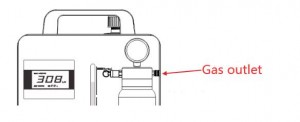

Situation 4. The gas outlet is blocked.

Solution: Use steel wire to poke through for several times until it is smooth.

Situation 5. The flame arrestor is blocked.

Solution: Remove the flame torch, block the right end of the arrest by hand, let the machine suffocate, when the machine stops working automatically, when the pressure gauge reaches 0.17Mpa, release the hand and observe whether the pressure gauge drops rapidly. If there is no rapid drop, the arrestor is blocked.

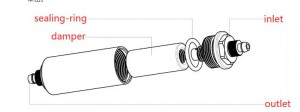

Step 1. Using a wrench, unscrew the arrestor counterclockwise.

Step 2. Unscrew the damper, soak it in hot water or boil it in hot water. Remove it after 20 minutes.

Note: If the damper is too dirty, replace it with a new one.

Step 3. Check the seal-ring and replace it if it is damaged.

Step 4. Check the air permeability of the inlet and outlet. If there is foreign matter, it can be soaked in hot water or boiled in hot water. Take it out after 20 minutes.

Situation 6. The flame torch is blocked.

Solution: Testing method as below:

Step 1. Turn off the flame torch, remove the nozzle. When the machine automatically stops working, the pressure gauge value reaches 0.17Mpa, turn on the flame torch, observe whether the pressure gauge drops rapidly. If the drop is slow, the flame torch is blocked.

Step 2. Turn off the flame torch. When the machine stops working automatically and the pressure gauge reaches 0.17Mpa, remove the flame torch and observe whether the pressure gauge drops rapidly. Compare the drop speed of the pressure gauge in the 2 times to further determine whether the flame torch is blocked.

Solution: Clean or replace the damper. Use a multiple functional wrench to unscrew the torch’s fastening screws, remove the damper, put it in hot water or cook it in hot water for 20 minutes. If the air is well reassembled and used, replace the new damper with poor ventilation.

Post time: Nov-08-2019