Popular Design for Discount Cnc Plasma - Hot Selling vacuum forming machine acrylic for plastic – YUANNUO MACHINERY Detail:

- Condition:

- New

- Type:

- Thermoforming Machine

- Plastic Type:

- Including but not limited to Acrylic, ABS, PVC etc

- Product Type:

- Acrylic sign, channel letter and light box

- Automatic:

- Yes

- Place of Origin:

- Shandong, China (Mainland)

- Brand Name:

- BEST or OEM

- Model Number:

- BT-3200V

- Voltage:

- 3 phase AC380V+/-10%

- Power(W):

- 18000

- Weight:

- 2000kgs, 2000kg

- Dimension(L*W*H):

- 335X235X230cm

- Certification:

- CE, ISO9001:2008

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Name:

- Plastic letter making machine

- Max. working width:

- 2000mm

- Max. working length:

- 3000mm

- Max. Shaping Depth:

- 200mm

- Power:

- 18kw

- Power Supply:

- AC380V+/-10% (3phase 4 lines)

- Functions:

- Press forming, blow forming and vacuum suck forming

- Dimension:

- 335x235x230cm

- Operation system:

- By hand controller or operation panel, switchable smartly

Packaging & Delivery

- Packaging Details

- Delivery Time

- 10 days after receiving deposit

Hot Selling vacuum forming machine acrylic for plastic

Dear customer,

Thank you for visiting our website.

We are professional manufacturer of Acrylic Vacuum Forming Machine and other AD sign equipment since 2008. This machine is mainly used to thermoforming Acrylic sign, acrylic letter and light box. There are 3 ready models for your selecting. Special model can be customized according to clients exact demand.

Please kindly contact us by e-mail, or skype or WhatsApp or telephone so that we can provide professional guide and save your valued time.

Thank you!

Picture show:

Specification:

|

Model |

BT-3200V |

|

Working Size (L*W) |

3000x2000mm |

|

Max. Shaping Depth |

200mm |

|

Max. Material Thickness |

8mm |

|

Heater Type |

Iron heating tube, durable, long working life |

|

Working Voltage |

3 phase AC380V+/-10% /50-60Hz |

|

Machine Overall Power |

18KW |

|

Machine Dimension |

335x235x230cm, 18.11CBM |

|

Gross Weight |

2000kg |

Application:

1.The machine is mainly used to make Acrylic Signs, Acrylic Letters, and Acrylic Light Box.

2.Applicable material including but not limited to Acrylic, ABS, PVC etc.

3.It is a useful and necessary and high efficiency equipment for Outdoor and Indoor Advertising making shop.

Samples as below:

Technical Feature:

1. It is a high integrated equipment with funciton of heating and softening, vacuum forming, blowing forming and compress forming.

2. Strong hydraulic lift system provide the machine with enough working pressure.

3. The machine is equipped with 3sets of Gear Rack And Pinion systemat each side, 6sets totally. Furthermore, there is a Link Pole between the 2 outside gear racks, it is useful to balance the movable board.

The above advantages of our machines make the movable board up and down more steadily, so the acrylic work piece made by the machine is higher quality and seldom defective goods created.

4. The machine is equipped with Control Panel and Hand Controller, both of them can control the machine. With the mobile Hand Controller, the working process can be observed in 360 degree full view by the user. Especially for the machine with vacuum forming and blowing forming function, the mobile hand controller is more useful. Take blowing forming for example, when you press down the "blow" button on the control panel, the gas flew can not be controlled according to actual forming status. But if you control by hand controller, when you press the "blow" button on it, the gas come out. When you find the product is finished properly, just need to release the button and gas will stop.

5. The heating oven is divided by 2 separate parts, they can work together or individually according to the material size.

6. The oven door is controled by pneumatic system, save working time and prevent heating escaping efficiently.

7. High precision temperature control system, digital display and will alarm automatically.

8. Special full steel structure and double roof beams make sure longer working life and more steady operation.

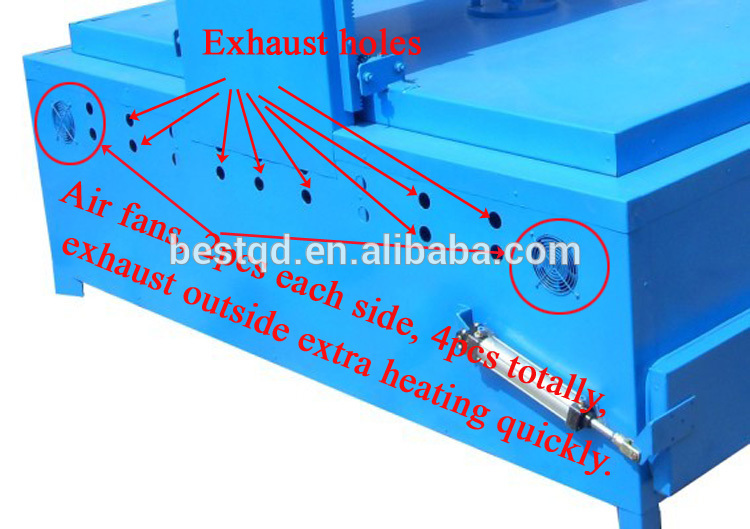

9. Our machine is equipped with 2pcs exhaust fans at each side, 4pcs totally.

Furthermore, we designed exhaust heating holes at 3 sides (right side, left side and back of the machine).

They are useful to exhaust extra heat created during the acrylic sheet is heated.

If extra heat can not be exhausted in time, it will be transferred to the worktable, so slower workpiece cooling speed or result in defective workpiece.

10. Our machine is equipped with metal heating tubes.Comparing with quartz heating tube, they are more durable and longer lifespan.

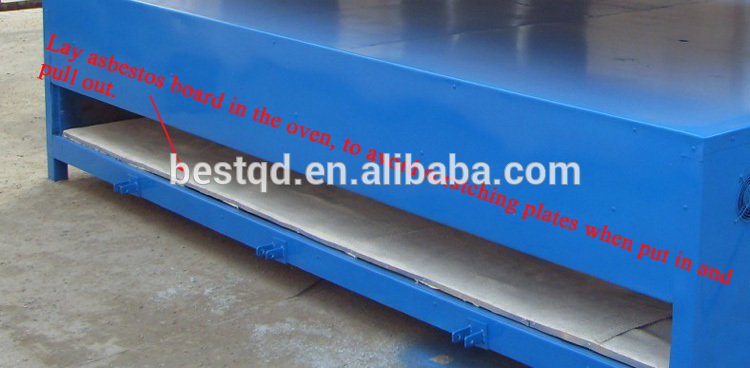

11) We cover the oven bottom with asbestos sheet to prevent scratching acrylic sheet when you put it and put out of the oven. The asbestos sheet is high grade fire proof material with high temperature-resisting characteristics. Except our company, now most of other manufacturers don’t use asbestos sheet any more so to save their cost.

Product detail pictures:

Related Product Guide:

Plastic Forming – Vacuum Forming Guide

A Lesson in Plastic Vacuum Forming and Its Role in Your Life

Popular Design for Discount Cnc Plasma - Hot Selling vacuum forming machine acrylic for plastic – YUANNUO MACHINERY, The product will supply to all over the world, such as: , , ,

-

Factory For Four Rollers Rolling Machine - Top...

-

OEM/ODM China Cutting Machine - Heavy duty CNC...

-

Wholesale Channel Letter Bender Machine - 1000...

-

8 Year Exporter Pvc Plastic Tube Bending Machin...

-

8 Year Exporter Plasma Metal Cutting Machine -...

-

Chinese wholesale Cnc Letter Making Machine - ...