Well-designed Bending Molding Of Acrylic Sheet - Multiple-lines automatic acrylic bending machine manual – YUANNUO MACHINERY Detail:

- Condition:

- New

- Place of Origin:

- Shandong, China (Mainland)

- Brand Name:

- BEST or OEM

- Model Number:

- BT-1200BS/BT-1800BS/BT-2400BS

- Machine Type:

- Hot bending

- Raw Material:

- Flat plate

- Material / Metal Processed:

- Plastic

- Power:

- Electric and Pneumatic

- Automation:

- Manual

- Extra Services:

- Heat Treating

- Certification:

- CE

- After-sales Service Provided:

- Overseas third-party support available

- Name:

- Multiple-lines Acrylic Bending Machine

- Model No.:

- BT-1200BS / BT-1800BS / BT-2400BS

- Heater type:

- Heating wires

- Heater q'ty:

- 4 parallel heating wires. More or less can be cusomized

- Heating voltage regulator:

- 4 sets to control 4pcs of heating wire separately

- Heating thickness:

- 10mm

- Max. distance between 2 next wires:

- 300mm

- Max. distance from 1st-4th wire:

- 900mm

- Power supply:

- AC220V single phase or AC380V 3 phase

- V-shape angle range to bend:

- 0-180 degree

Packaging & Delivery

- Packaging Details

- Delivery Time

- Shipped in 15 days after payment

Multiple-lines automatic acrylic bending machine manual

Description of Multiple-lines Acrylic Bending Machine

|

|

1. Equipped with 4 heating lines, can heat and bend max. 4 parallel angles meantime. 2. Equipped with heating wires, can form more accurate and sharper angle. 3. Every heating wire is controlled individually. 4. Heating voltage of each wire is controlled and adjusted by one separate voltage regulator. 5. Distance between 2 next wires can be adjustable in range of 0-300mm. Max. Heating width between the 1set wire and the 4th wire is 900mm. Click here to watch video |

Technical Specification

|

Model No. |

BT-1200BS |

BT-1800BS |

BT-2400BS |

||

|

Heating Lines Number |

4pcs of wires (heating tubes are optional, no cost increase) |

||||

|

Min. Width between 2 next heaters |

40mm |

||||

|

Max. Average Width between 2 next heaters |

300mm (Every line is controlled on or off individually. The 1st bending line is fixed, the other 3 lines are adjustable to left or right.The whole width between the leftmost to the rightmost lines is 900mm.) |

||||

|

Bending Length |

0-1200mm |

0-1800mm |

0-2400mm |

||

|

Bending Thickness |

0-10mm directly, thicker sheet can be bent after milling thinner in advance |

||||

|

V-shaped Angle Bending Range |

0-180 degree |

||||

|

Heating Mode |

Non-contact infrared heating |

||||

|

Power Supply |

AC220V+/-10% 50-60Hz or AC380V+/-10% |

||||

|

Dimension (L*W*H cm) |

185x120x105CM 2.33CBM |

245x120x105CM 3.08CBM |

305X120X105CM 3.84CBM |

||

|

Net Weight (kg) |

200 |

260 |

300 |

||

|

Weight (kg) |

230 |

300 |

380 |

||

Pictures of Multiple-lines Acrylic Bending Machine

Technique features

1.The machine is equipped with 4 heating lines, so it can heat and bend max. 4 parallel angles meantime, is 4 times working efficiency higher than common bending machine. More or less heating lines can be customized according to clients requirement;

2. The machine is equipped with heating wires, comparing with heating tubes, it can form more accurate and sharper angle;

3. Every heating wire is controlled individually. You can make them work together, or select ones of them working and the others off freely;

4. Heating voltage of each wire is controlled and adjusted by one separate voltage regulator;

5. Distance between 2 next wires can be adjustable in range of 300mm. So max. Heating width between the 1set wire and the 4th wire is 900mm;

6. When 4 wires working meantime and every voltage regulator is set on the max. Value 75V, the overall power of the BT-1200BS machine is 1.6kW, BT-1800BS machine 1.7kW, BT-2400BS machine 1.8kW.

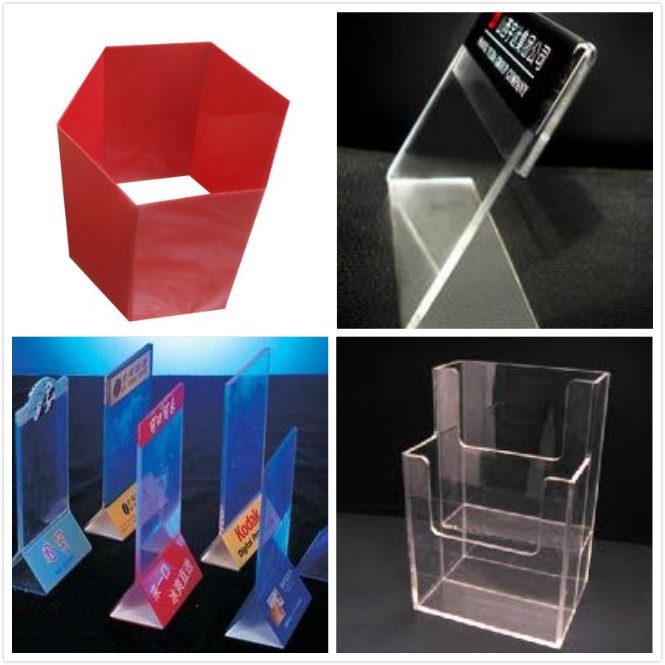

Application

It is widely used to bend hard plastic sheet, including but not limited to acrylic (organic, PMMA), PC, PVC, PETG, PP, ABS etc. V-shaped angle bending range is 0-180°. Max. circular arc diameter is 30mm. It is a necessary equipment for AD sign products making industry. Proper for sample making and mass production. Samples as below

Wrranty

1. 2 years dating from buyer receiving the machine. More than 1 year than other suppliers’ warranty period.

2. During warranty period, if some part is broken or damaged due to manufacturing defect, we will provide new one to replace by free cost and and free shipping.

3. We provide technical supporting during the whole lifespan of the machine.

So it is more safe guard for your to purchase from us than from other suppliers.

Delivery Time

- 3-5 days after payment is received.

Warranty and after sale service

- 12 months dating from buyer receiving the machine.

- During warranty period, if some part is broken or damaged due to manufacturing defect, we will provide new one free cost to replace.

- When warranty period is expired, if some part is broken or damaged, you can buy new from our company.

We provide you free cost technical supporting during the whole lifespan of the machines. If you have any questions to the above, please don’t hesitate to contact with us. Thank you for your kind attention!

Product detail pictures:

Related Product Guide:

A Lesson in Plastic Vacuum Forming and Its Role in Your Life

Why Natural Gas Generator for Home Is Your Best Option?

Well-designed Bending Molding Of Acrylic Sheet - Multiple-lines automatic acrylic bending machine manual – YUANNUO MACHINERY, The product will supply to all over the world, such as: , , ,

-

Competitive Price for Pipe Threading Machine -...

-

Factory selling Acrylic Sheets With Bamboo - 2...

-

OEM Customized Petroleum Gas Generator - Onlin...

-

OEM Factory for Natural Gas Generator Price - ...

-

Factory wholesale Metal Cutting Cnc Machine - ...

-

Reasonable price for Single Cylinder Crankshaft...